Completed Committee Project Fund Awards

CRSI Design Handbook Update

Updates to the CRSI Design Handbook tables used for pile design reflecting higher strength steel pipe piles (capacities up to 900 tons).

$15,000

Comparison of Impact Versus Vibratory Driven Piles: With a Focus on Soil-Structure Interaction

Study of factors that influence vibrodriveability, pile behavior and axial and lateral capacities of vibratory and impact driven piles.

$28,000

DFI Vibratory Hammer Data Collection

The data collected through the vibratory hammer submission system will be shared among DFI committee members and partner organizations to compile and complete studies related to vibratory driving of piles for foundations and earth retention.

The initial study will focus on piles where most of the pile driving was done with a vibratory hammer before completing it with an impact hammer.

The driving records at the end of vibratory driving will then be compared with the records at the beginning of impact driving to validate signal matching methodologies to estimate the capacity of piles installed with a vibratory hammer without the need for final impact driving.

Follow-on studies may be conducted based on the results of the initial study.

Cost Effective Pile Project Case History Library

Collection of case histories that illustrate how driven pile foundations can take advantage of cost-saving design and installation factors to contribute to a cost-effective design, including:

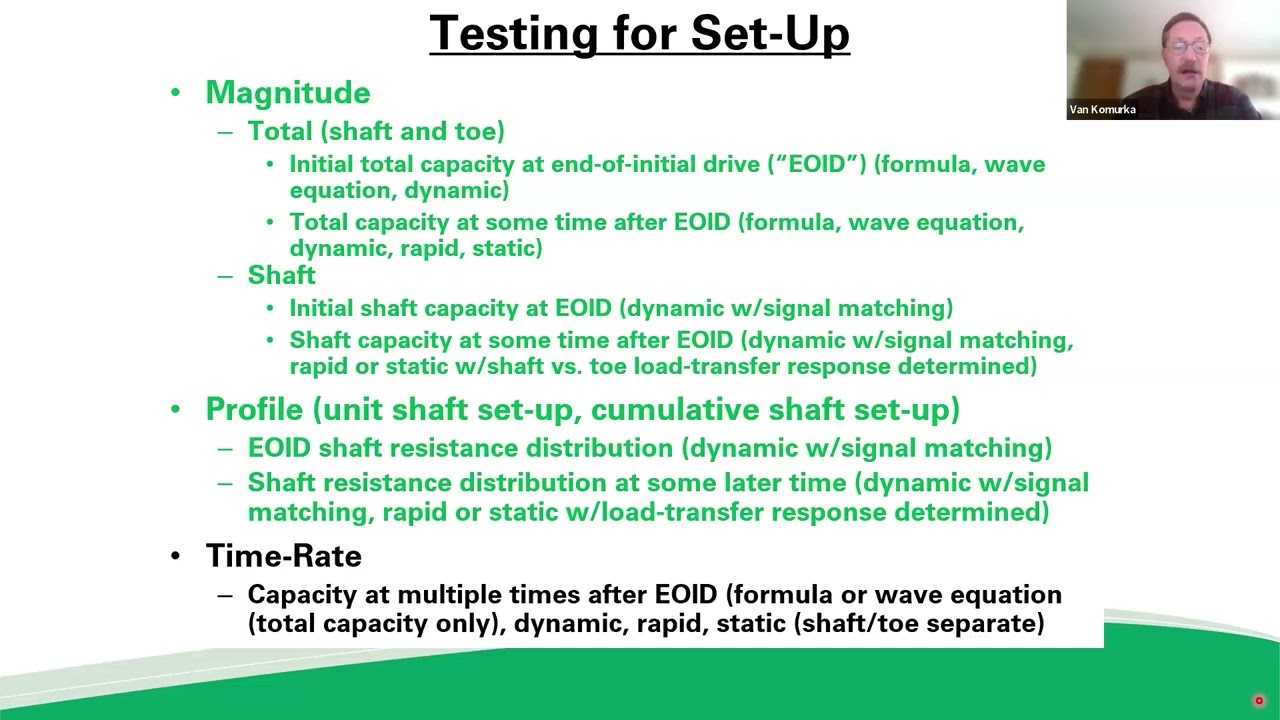

- Soil/Pile set-up

- Testing

- Higher allowable loads

- Design stresses

- Pile type

- Driving criteria

- Pile material

- Matching allowable loads to column loads

Promote and Support the Design, Construction and Equipment Supply for Marine Foundation Projects

DFI’s former Marine Foundations committee is now operating under the Driven Pile committee and is continuing these ongoing initiatives:

!mpact Webinar Series

Webinars highlighting innovative developments, case studies and current practices of driven pile foundations.

Playlist

Crane Lift Charts Specific to Driven Pile Subcommittee

Examining formulas used for crane lifting and supplying a single-spot resource for manufacturer details to further the conversation about safe crane lifting of pile driving equipment.

Geotechnical in Pile Driving Subcommittee

Exploring driven pile specific considerations for collecting and designing with geotechnical characterization data, understanding soil borings, sizing and tooling the equipment for project-specific soil conditions, and reading and implementing the recommendations in geotechnical reports.

Safety in Driven Pile Subcommittee

This task force is producing a safety briefing six times per year to “tell stories on what you have seen.”

Social Media Subcommittee

Leveraging social media tools to highlight advancements and innovations in driven pile technology and achievements of the DPC and its members and companies.

ASTM and State Specifications

Hosting an industry-wide conversation about driven pile related specifications, the industry’s relationship with ASTM, and state-specific provisions to advance mutually beneficial industry practices.

Mid-sized Diameter Pipe Study

Studying the use, design, and performance of mid-size diameter pipe piles.