Home / Communities / EFFC/DFI Task Groups

EFFC/DFI Task Groups

The European Federation of Foundation Contractors works to promote the common interests of its members by improving the standard of workmanship, technical competence, safety and innovation for specialist foundation contractors across Europe.

DFI and EFFC collaborate on areas of mutual interest through task and working groups related to concrete mixes, support fluids, working platforms and sustainability.

EFFC/DFI Concrete Task Group

Formed in 2014 to address the issues that contractors experience on site with modern concrete mixes.

Group Chair

Karsten Beckhaus, Ph.D.

BAUER Spezialtiefbau GmbH

Karsten obtained his University degree in Civil Engineering, and later his doctoral degree, from the Technical University in Munich, Germany, where he did research work, assisted in teaching students in material technology, and managed the scientific concrete group testing lab.

Karsten is now leading the Services Division of Bauer Spezialtiefbau GmbH which assists Bauer’s projects worldwide, in specialist technical tasks, including material technology. Beside the evolution in technical matters, Karsten also works on standardization, amongst others in particular for standards on design and execution of special geotechnical works, and on design and testing of concrete, soil-cement mixes and others.

EFFC/DFI Guide to Tremie Concrete for Deep Foundations

The European Federation of Foundation Contractors (EFFC) and the Deep Foundations Institute (DFI) published the 1st Edition of the EFFC/DFI Guide to Tremie Concrete for Deep Foundations in 2016. A research and development project, funded by the sponsors of the Guide, and carried out by the Technical University of Munich in conjunction with the Missouri University of Science and Technology was completed in 2018. The 2nd Edition of the Guide was published in June 2018 and this includes results from the research and development program including numerical modelling studies of concrete flow. Numerical modelling gives a better understanding of the interaction between design, concrete properties, and execution methods.

The 2nd Edition of the Guide presents a review of concrete rheology, its dependence on raw materials and composition, applicable testing methods and recommended target values, as well as providing recommendations on specific design and execution details. It is intended as a practical addition to existing standards, although it is hoped that after implementation and review in practice, the principles contained in the Guide will be adopted in future revisions of Standards. Recommendations on support fluids have been removed from the 2nd Edition as these are now covered by the EFFC/DFI Support Fluid Guide which was published in 2019.

Research Report: Rheology and Workability Testing of Deep Foundation Concrete in Europe and the US

A companion research report to the DFI/EFFC Guide to Tremie Concrete for Deep Foundations (2nd Edition) which provides information on the research incorporated in the guide that numerically models the behaviour of concrete when it is poured into an excavation. This is a new area of research which provides new insight into what is occurring during the tremie operation.

Update: Plans for Third and Fourth Editions

The EFFC/DFI Concrete Task Group (CTG) is currently finalizing the Third Edition of the ‘Guide to Tremie Concrete for Deep Foundations’ (Tremie Guide). It is planned that the Third Edition will be released in the last quarter of 2024.

The Third Edition will broadly follow the scope and structure of the Second Edition. In addition to this general update, users have requested clarification on a number of matters which will now be covered in the Third Edition which include:

- options to reduce greenhouse gas emissions

- strengthening the recommendations regarding acceptance criteria for testing

- interesting new findings from numerical modelling

Work has also commenced on the Fourth Edition which will require another two years of hard work by the CTG. The major additions to the Fourth Edition will include:

- harmonising the Tremie Guide with the new EN 206 Part 3 which will specifically include additional requirements for concrete in geotechnical works. This will replace the current Annex D in EN 206-1. This inclusion is very significant and most of the new requirements are based on the recommendations in the EFFC/DFI Tremie Guide.

- harmonising the Guide with ACI 336. This is a huge step forward in applying the most suitable test methods and acceptance criteria to modern tremie concrete.

- further detailed numerical modelling studies to understand concrete flow mechanisms, especially in the design of concrete for challenging geotechnical works. The CTG has been working closely with a number of academic groups who are doing this work. Further time is required for the results to be evaluated and checked and collated.

EFFC/DFI Support Fluids Task Group

Established in 2017 to investigate the preparation, characteristics and testing of support fluids.

Group Chair

Christophe Justino, M.Sc.

Soletanche Bachy International

Christophe Justino M.Sc. (Eng.) is the manager of the materials department at Soletanche Bachy. He has nearly 20 years of experience focused on materials for geotechnical works on an international scale. The scope of Christophe’s works ranges from concrete technology, designing grout materials and drilling fluids, deep foundation works, and providing technical assistance and expertise. He is an active member of French federation for civil works at the material committee and chairman of the support fluid task group at the EFFC (European Federation of Foundation Contractors).

EFFC/DFI Guide to Support Fluids for Deep Foundations

This guide represents the state of the art of support fluid practice and aims to improve existing design, testing and practices for deep foundation elements – bored piles (drilled shafts), barrettes (LBEs) and diaphragm wall panels. It represents the first time that knowledge of good practice from around the world has been brought together into a single authoritative publication. The purpose of this Guide is to present current understanding on bentonite, other clays, polymers and blended systems, including the advantages and limitations, in order to allow informed selection of the optimum technical solution(s) for the conditions on each individual worksite. This Guide does not recommend any particular type of support fluid as each worksite has specific characteristics and requirements.

This Guide will assist individuals and corporations involved in the procurement, design, and construction of deep foundations including Owners/Clients, Designers, General Contractors, Academics and Specialist Contractors. It is intended as a practical addition to existing standards, not a substitute. Project Specifications, Standards and Codes should always take precedence. This first edition details accepted industry good practice and will be followed by a second edition based on a comprehensive R&D program which will carry out a series of field research studies. The studies will collect data from active project sites and develop and conduct non-standard tests in order to establish what testing methods have substantial value and to better understand the validity of the compliance values in use. The task group will then produce a second edition of the guide that promises to be the best authority on the use of support fluids in the industry. This is expected to be published in 2023.

EFFC/DFI Working Platforms Task Group

The EFFC/DFI Working Platforms Task Group pools the experiences across the membership of EFFC and DFI to collaborate on the critical issue of improving the safety of working platforms. Working platforms are used by everyone that accesses a site, particularly cranes and drilling machines.

Group Chair

Peter Faust, Dipl.-Ing.

Malcolm Drilling Company, Inc.

Peter Faust has 30 years of professional experience in the design and construction of foundations. He graduated from Technical University Graz in Austria with a Masters in Geotechnical Engineering. After being involved in project management and the engineering of large and complex infrastructure projects in Asia and Europe, he joined Malcolm in 2006. He is responsible for business development, strategic planning, and managing corporate communications, and marketing.

Faust serves as DFI’s Trustee and has also contributed to the efforts of EFFC and DFI, publishing a series of 3 guidelines about Tremie Concrete, Support Fluid and Working Platforms for Deep Foundations.

Guide to Working Platforms

On a typical construction site, the provision of a safe surface to work on involves and affects a number of the contracting parties (the client; principal designer; general contractor; specialty contractor; platform designer; platform installer or earthworks contractor; platform tester and platform maintainer), and as a consequence, the organization of its design, installation and maintenance can be complex. This document takes each step in turn and describes what good practice is, with reference to documents and resources that have been made available through the EFFC and DFI.

A current initiative of this task group is to update this guide with leading research into which methods of design and verification are the most appropriate to use. It is also hoped that better guidance regarding applicable track pressure can be developed. These results shall enable us to provide better guidance on how to minimize the risk of a failure in the working platform. If you wish to participate in this effort, please contact DFI or the Group Chair directly.

Field Research Study (FRS) #1

Verifying the quality of the platform is difficult and can be expensive to carry out. To understand the best methods for testing and seek a practical solution to this problem EFFC and DFI have created a program of comparative assessment of different testing techniques. This is being carried out in the US and Europe at several sites. The aim is to find a cost-effective and simple way to assess whether a working platform is fit for purpose before and during the works. Please contact the Group Chair if you are interested to participate.

Field Research Study (FRS) #2

Most manufacturers provide track pressure values following the requirements of EN 16228. However, the actual pressures exerted during the operation of the rig may be different as this is dependent on the configuration of the machine and the site conditions. Recognizing that there may be significant variation in loading applied by nominally similar rigs due to manufacturing variations, user modifications and nature of operation, each contractor should provide the platform designer with the operational track pressure and load areas for a project.

This is a bit of a challenging task, which leads to the purpose for Field Research Study (FRS) #2: to provide a more user-friendly summary of applicable track pressures that owners, consultants, designers, general contractors, as well as specialty contractors, can use to estimate track pressure, for at least a preliminary evaluation. The attached table is a first draft in this effort. The Task Group welcomes your comments on this draft, which you can provide by emailing the Group Chair.

Field Research Study (FRS) #3

How can we ensure different working platform design methods produce more consistent results? Even using the same base data sets can produce widely varying results. Therefore, we are developing a research proposal to perform a sensitivity analysis on input parameters for the design methods. The intention is to reduce the current variance in thickness to a tighter, more consistent range, regardless of design method, by identifying the most influential parameters. It is not the intention of the Task Group to recommend any particular design method. Rather the Task Group aims to improve the process so that better understood parameters are used in platform design, and once it is constructed, the design assumptions can be properly tested before and during use. The group is in discussion with the University of Stuttgart, Germany to build on research they have already undertaken on platform design.

Additional Resources

EFFC/DFI Carbon Calculator Task Group

Developed a standardized tool called the Foundation CO2 Calculator which calculates the carbon footprint of deep foundation and ground improvement works.

Group Co-Chairs

Luca Bruni

Injectosond Italia

Luca Bruni is a civil engineer born in Albisola Superiore (Savona-Italy) who possesses a master degree in civil structural engineering. His career began in 1999 in at the University of Arizona where he served as an intern with the Aerospace and Mechanical Engineering Department to prepare for his thesis on carbon and composite structural materials applied to civil engineering. From 2000-2002: he worked for Injectosond Italia Srl as a technical employee and quality manager developing the first ISO9002 quality system certifications.

From 2003-2018 Bruni worked for Servizi E Costruzioni Srl specializing in deep foundations as their technical director and QHS Manager for ISO9001-OHSAS18001. During that time he served as a member of the European Federation of Foundation Contractors (EFFC) Carbon Calculator Technical task group which developed with Deep Foundations Institute (DFI) the first software at the European level for the calculation of CO2 emissions for the foundation industry and served as it’s chairman from 2015-2018.

Following these roles, Bruni went to work for Malabaila & Arduino France sarl, then ICOSE SpA and then back to Injectosond Italia Srl. In 2022, EFFC and DFI reingnited the task group and he is co-chair representing EFFC.

Chris Nelsen

Delve Underground

Chris Nelsen is a Geotechnical Engineer at Delve Underground, formerly McMillen Jacobs Associates, with 5 years of geotechnical engineering experience. Chris joined McMillen Jacobs Associates after three years as a field/project engineer for Keller. His areas of expertise include design, installation, and QA/QC of geostructural elements. He is developing expertise in site investigation, soil and rock characterization, support of excavation design, and tunnel construction impact analyses.

Chris is also engaged in industry-wide efforts to improve the sustainability of infrastructure projects through the ISI framework as an Envision Sustainable Professional (ENV SP). Incorporating sustainability into his day-to-day personal and work activities has been a growing theme and passion throughout Chris’ life.

EFFC/DFI Carbon Calculator

The EFFC/DFI Carbon Calculator has been developed using verifiable, standardised data to enable accurate benchmarking of competing project proposals. Prior to its development there existed no single standardised tool for calculating CO2 emissions for these types of ground works.

The tool also allows contractors to compare and contrast different technical approaches within the same project and see what the CO2 emissions will be. Furthermore it can be used throughout a project’s development to compare how it performed against expectations.

EFFC/DFI Carbon Calculator Webinars

Playlist

EFFC/DFI Carbon Calculator Training Video

This webinar explains why carbon reduction is important and how to reduce emissions by measuring your carbon footprint. The workshop will also guide you through the industry’s leading tool; the EFFC/DFI Carbon Calculator, a free aid which allows the user to assess the carbon footprint of their project.

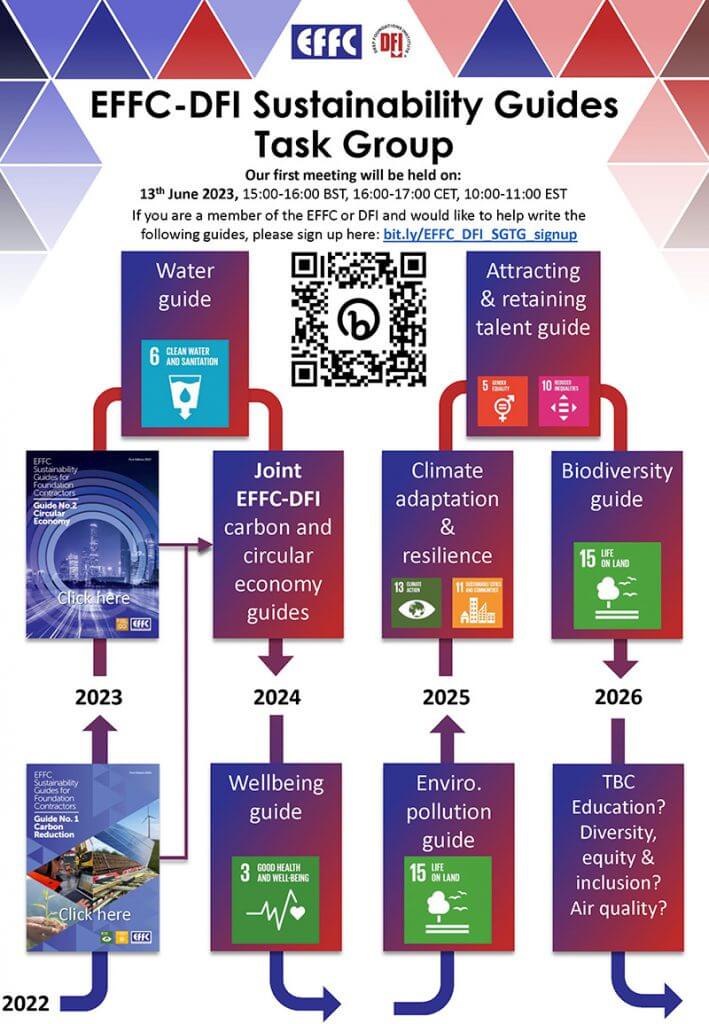

EFFC/DFI Sustainability Guides Task Group

To write practical, actionable guidance that helps geotechnical companies improve their sustainability. The Task Group aligns these guides to the UN Sustainable Development Goals, further focusing on the most material goals for geotechnical companies.

Group Co-Chairs

Luke Deamer, Eng.D, ME.Sci, FGS

Keller

Luke Deamer is group sustainability manager for Keller. He has a doctorate in sustainability from the University of Surrey, focused on improving sustainability across all functions of a geotechnical company. Deamer is based in the U.K. and is currently co-chair of the EFFC-DFI Sustainability Guides Task Group. He is also a member of both the Federation of Piling Specialists (FPS) and EFFC sustainability working groups. His previous roles have included working as a structural geologist on the Panama Canal and the Oman Drilling Project.

Deamer has authored several papers and guides on geotechnical sustainability. He wrote the EFFC’s Sustainability Overview, and co-authored both the EFFC’s Carbon Reduction Guide and Circular Economy Guide. He also has been published in academic publications, including articles on applying the carbon hierarchy to geotechnical contractors (ICE), pre-qualification questionnaires (ICE) and building sustainability from the bottom up (Sustainability). Luke has an integrated Earth Science master’s degree in geology (with Honours) from Cardiff University.

Kimberly Martin, Ph.D., P.E., ENV SP

Keller, North America

Kimberly Martin is a senior engineer at Keller-NA. In her current role, she is responsible for developing and implementing Keller’s sustainability strategy in North America, which includes leading innovation initiatives to support Keller’s carbon targets. She previously worked in the oil and gas industry as a lead geotechnical engineer on development projects across the globe.

She is the past chair of the Arizona Geo-Institute and is the current secretary of the Geo-Institute’s Sustainability in Geotechnical Engineering Committee. Martin also sits on DFI’s Sustainability Committee and serves as co-chair of the EFFC-DFI Sustainability Guides Task Group. In addition, she is a member of the editorial panel for Engineering Sustainability, a journal published by the Institute of Civil Engineers.

Martin has published more than 10 peer-reviewed journal and conference papers. Martin holds a bachelor’s degree in civil Engineering from the University of Arizona, a master’s degree in geotechnical and geo-environmental engineering from The University of Texas at Austin, and a Ph.D. from Arizona State University, where she was a member of the Center for Bio-mediated and Bio-inspired Geotechnics.

Guides Overview

These guides follow a basic what, why, how, measure approach:

What

What is this specific area of sustainability? What impacts do foundation contractors have on this goal?

Why

Why does this area of sustainability matter to foundation contractors? Why should they bother to improve this area of sustainability?

How

How can foundation contractors improve their impact and positively impact this area of sustainability?

Measure

What metrics could foundation contractors use to measure their progress and set targets in this area of sustainability?